_

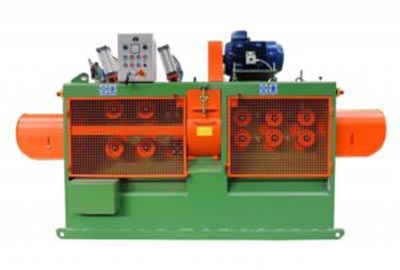

DNAA REELING MILL

DNAA reeling mills – 140, 160, 200, 240 are designed for accurate reeling of wooden rollers and stakes.

This machine is EC certified.

The machines may be available on request, e.g., including enhanced power feed parameters, and pneumatic pressure on the reception. The DNAA reeling mills – 140, 160, 200, 240 are designed for accurate reeling of wooden rollers and stakes. This machine is EC certified.

| TECHNICAL SPECIFICATION | ||||

| DNAA - 140 | DNAA - 160 | DNAA - 200 | DNAA - 240 | |

| Range of diameters to be obtained | Ø 50- Ø 140 mm | Ø 50- Ø 160 mm | Ø 80- Ø 200 mm | Ø 120- Ø 240 mm |

| Maximum diameter of wood prior to machining | Ø 200 mm | Ø 220 mm | Ø 280 mm | Ø 320 mm |

| Maximum machining allowance | 30 mm per page | 30 mm per page | 40 mm per page | 40 mm per page |

| Minimum length of machined elements | 700 mm | 700 mm | 1000 mm | 1000 mm |

| Supply voltage | 3/N/PE AC 400/230 – 50Hz | 3/N/PE AC 400/230 – 50Hz | 3/N/PE AC 400/230 – 50Hz | 3/N/PE AC 400/230 – 50Hz |

| Rate of travel (CVT) including AUTO-FIT system | 3 ÷ 12 m/min | 3 ÷ 12 m/min | 3 ÷ 10 m/min | 3 ÷ 10 m/min |

| Feed engine power | 2,2 kW | 2,2 kW | 3 kW | 3 kW |

| Tool-head drive engine power | 22 kW | 22 kW | 30 kW | 30 kW |

| Head rotation speed | 1910 obr./min | 1670 obr./min | 1240 obr./min | 1034 obr./min |

| Pressure of rollers at the material delivery | Pneumatic | Pneumatic | Pneumatic | Pneumatic |

| Pressure of rollers at the material exit: | Mechanical /Spring | Mechanical /Spring | Mechanical /Spring | Mechanical /Spring |

| Air demand for sawdust draft: (in case of sawdust side draft) | 2000 m3/h | 2000 m3/h | 3500m3/h | 3500m3/h |

| Overall dimensions (L x W x H) | 2610x1070x1250 | 2610x1070x1250 | 3100x1200x2000 | 3100x1200x2000 |

| Weight of the machine including switch-box | 2100 kg | 2200 kg | 3200 kg | 3240 kg |

| Reeling mill standard equipment: | Cutters – 1 set. Tool for cutter contact adjustment – 1 pc. Set of discs for the foregoing tool – 1 pc. Gauge for cutter adjustment – 1 pc. Pilot sleeves – 1 set Key to switch = box – 1 pc. Operation and maintenance documentation – 1 pc. | |||

| Special-purpose equipment (on client's request) | Feeding and receiving roller conveyor – 2 x 3 linear meter Set of toothed intermediate rollers |

_